Question

Our nuclear test facility has just shut down one of our onsite reactors for scheduled maintenance. We have sixteen Endevco® model 2771X-X charge amplifiers on hand, all of which are presently of unknown condition. Due to the high risks associated with a potential radiation hazard, we are unable to return these units to the factory for evaluation. Could you provide us with a simple procedure to perform a GO-NO-GO test?

Answer

To simply determine whether on-hand instrumentation is functional or operational when instrumentation return is not possible, a GO-NO-GO test can certainly be performed. While somewhat limited, in terms of its ability to provide specific parameters, this type of testing offers a quick and accurate means of checking system functionality. The following procedure is applicable to Endevco models 2771A, 27712B and 2771C charge amplifiers and is intended for a GO-NO-GO testing situation only:

Parts List:

C1 1000 pF capacitor

C2 0.1 mfd capacitor 50V

R1 100k resistor 5%

D1 IN5314 Diode

Test Equipment:

Oscilloscope

Volt Ohm meter

Signal Generator

+24Vdc Power supply

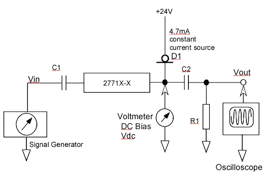

Figure 1

To conduct the test:

1. Hook up the circuit as shown above.

Set the signal generator output to minimum and turn power on. Apply a 24V, 4.7 mA constant current power source to the Model 2771X charge amplifier and allow the bias to settle for about two minutes. The bias voltage should be within specification. Units that are out of specification are defective.

2. Inject 100 pico-coulomb rms of charge to the input of the Model 2771X-X charge amplifier at 1000 Hz.

Set the signal generator frequency to 1000 Hz sine wave. Slowly increase the signal generator output voltage (Vin) to 100 mV rms. Monitor the output (Vout) using an oscilloscope across R1. You should be seeing a clean sine wave. Distorted output indicates a non-performing charge amplifier.

The charge injected Q is given by: Q=CV, where:

V = 100 mV rms; C = 1000 pf; and

Q = 100 mV rms x 1000pF = 100 pC rms

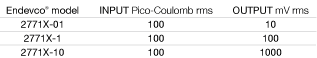

3. Measure the output voltage (Vout) across R1 (100K). The table below shows typical outputs corresponding to different dash numbers (gain). Compare these results with the published product specification .

Figure 2

It is important to emphasize that the intent of this established procedure is solely to provide quick onsite testing of instrumentation that has been used or stored in hazardous environmental conditions, precluding their return for factory evaluation. It is not intended to replace in-house factory evaluation of instrumentation, nor does a GO-NO-GO test provide diagnostics of specific instrumentation problems, nor does it offer verification of system survivability within a given testing environment. It is, however, a strong means of offering "pass-fail" decision making at the customer site on the status and functionality of key system components. For more information about these and other types of simple test procedures, contact us at applications@endevco.com.